An overview of the SAREF4INMA ontology is provided in Figure 1, where rectangles containing an orange circle are used to denote classes created in SAREF4INMA, while rectangles containing a green circle denote classes reused from other ontologies, such as SAREF or SAREF4BLDG. For all the entities described in the present document, it is indicated whether they are defined in the SAREF4INMA extension or elsewhere by the prefix included before their identifier, i.e. if the element is defined in SAREF4INMA the prefix is s4inma, while if the element is reused from another ontology it is indicated by a prefix according to Table 1 (e.g. saref refers to SAREF and s4bldg refers to SAREF for building).

Arrows with white triangles on top represent the rdfs:subClassOf relation between two classes. The origin of the arrow is the class to be declared as subclass of the class at the destination of the arrow.

Directed arrows are used represent properties between classes.

Note that Figure 1 aims at showing a global overview of the main classes of SAREF4INMA and their mutual relations.

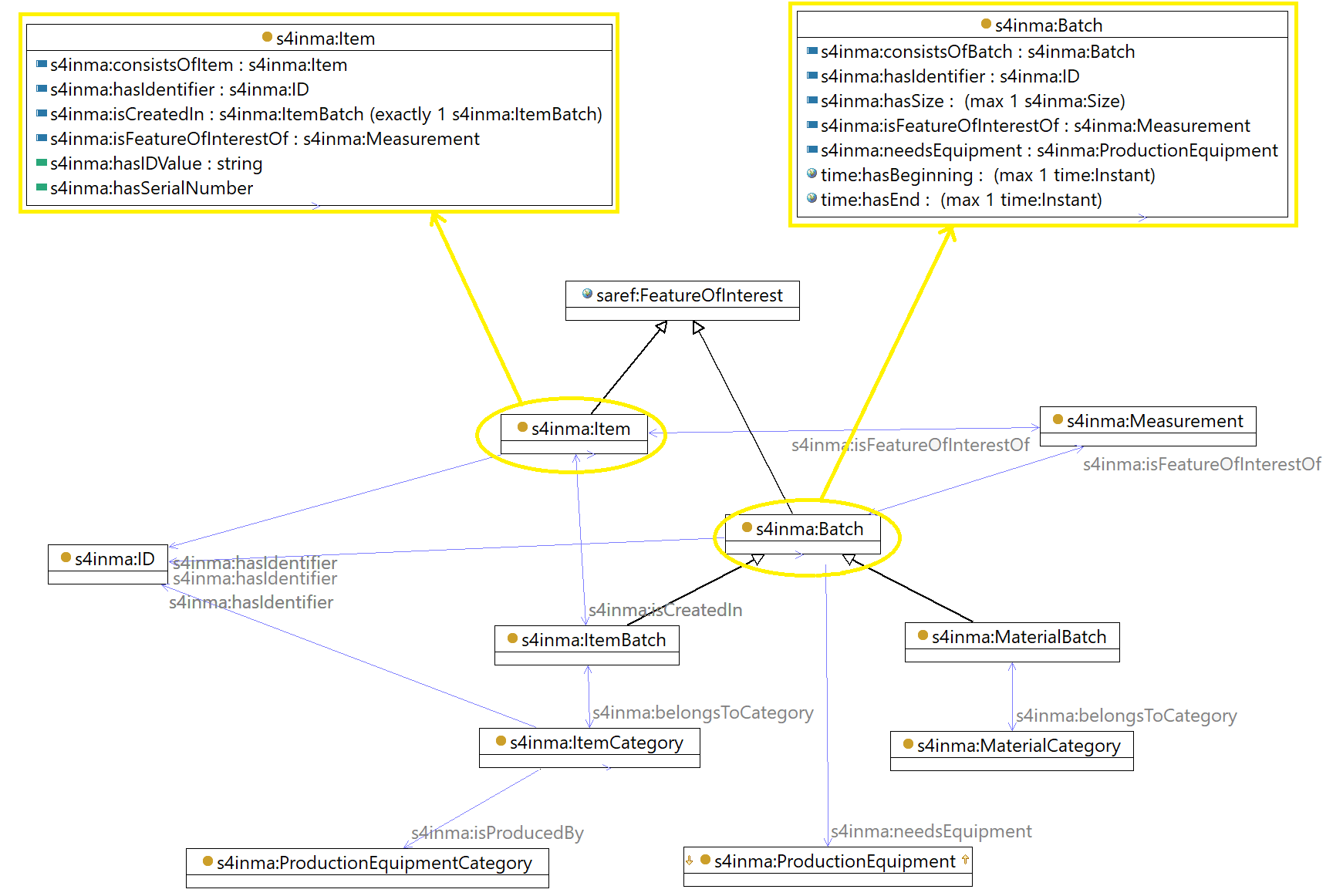

This clause focuses on the classes of SAREF4INMA that describe an item produced in a factory. The classes of interest, which are s4inma:Item, s4inma:ItemCategory, s4inma:MaterialCategory, s4inma:Batch, s4inma:ItemBatch, s4inma:MaterialBatch and s4inma:ID, are shown in Figure 3.

An Item is a tangible object that represents either the goods produced by an organization's production process or individually traced supplies (i.e. sub-assemblies of supplies). An item can be individually traced using an ID. SAREF4INMA allows to use several types of IDs, such as the Global Trade Item Number (GTIN) defined by GS1 (https://www.gs1.org/), used by organizations to uniquely identify their trade items as products or services that are priced, ordered or invoiced at any point in the supply chain. There are four GTIN formats (GTIN-8, GTIN-12, GTIN 13, GTIN-14) and SAREF4INMA defines classes and properties for each of them. SAREF4INMA defines also classes and properties to associate items to the International Registration Data Identifier (IRDI), which is based on the international standards ISO/IEC 11179-6 [i.4], ISO 29002 [i.5] and ISO 6532 [i.6]. An example of relevant standard that uses IRDIs is the eCl@ss specification (https://www.eclass.eu/en/) for grouping materials, products and services. Other types of IDs are defined in SAREF4INMA, such as the Universally Unique Identifier (UUID), or can be further defined ad-hoc by the ontology users by creating new classes as subclasses of the s4inma:ID class.

An Item can recursively consist of other items (e.g. a shaver consists of a shaver head, motor and body) and can be the feature of interest of a measurement (e.g. a shaver can be the feature of interest of a temperature measurement made by a welding machine used to join different parts in the production of the shaver). An item is created exactly in one ItemBatch, which describes a uniform collection of items produced at a certain time using a certain production equipment. An ItemBatch consists of a set of items with similar properties (e.g. a certain brand and model of sensors made using a certain production line). An ItemBatch is a specialization of the more general Batch, which can be further specialized in a MaterialBatch. The difference between ItemBatch and MaterialBatch is that individual items can be traced in an ItemBatch (e.g. it is possible to trace an individual metal sheet in an ItemBatch), whereas it is not possible to exactly trace material in a MaterialBatch, (e.g. it is not possible to trace the exact piece of raw plastic material from a MaterialBatch, as the raw plastic is a volume, not identifiable in a specific sheet like in the case of metal sheets).

Material batches can be equipped with quality certificates, such as the BS EN 10204:2004 [i.7] category 3.1 steel quality certificate (https://standardsdevelopment.bsigroup.com). These certificates provide additional information about the material in the batch. Furthermore, MaterialBatches belong to some MaterialCategory, which describes a certain type of material (e.g. a certain type of steel sheets). Analogously, item batches belong to some ItemCategory, which describes a single type of Items (e.g. a certain type of sensor). An ItemCategory is in turn produced by some ProductionEquipmentCategory. The essential properties of each Item in all ItemBatches are the same. However, each ItemBatch might use different MaterialBatches and/or different ProductionEquipment. Therefore, small deviations between batches might occur, while the essential properties of all Items related to an ItemCategory are similar. Finally, the time that a batch is produced can be recorded using the time:hasBeginning and time:hasEnd properties.

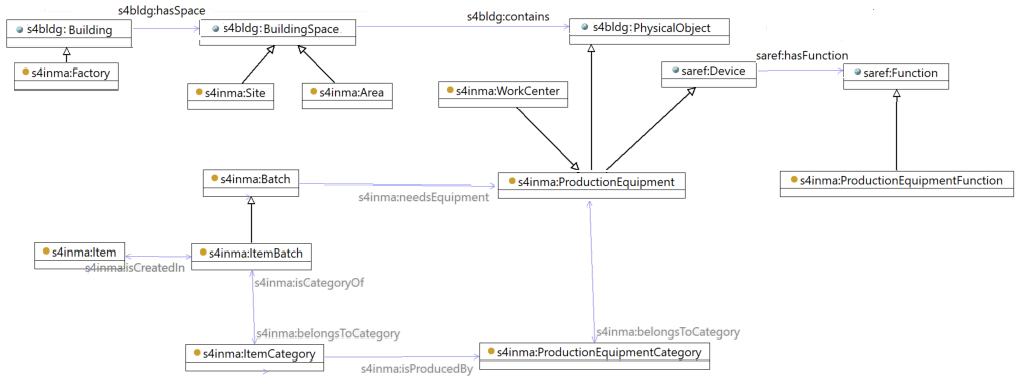

This clause focuses on the classes that describe how a production equipment is organized and how it can exchange information within the factory. The classes of interest are: s4inma:ProductionEquipment,s4inma:ProductionEquipmentCategory,s4inma:WorkCenter, s4inma:Area, s4inma:Site, and s4inma:Factory, and are shown in Figure 4.

A ProductionEquipmentCategory describes the kind of production equipment required for producing a certain item, i.e. a category of machine. An organization might have multiple instances of the same category of machines. Each individual machine is represented by a ProductionEquipment, which is a subclass of saref:Device, which is in turn a subclass of s4bldg:PhysicalObject. The latter is part of the SAREF for Building extension [i.3], which defines the saref:Device class as a subclass of the more general s4bldg:PhysicalObject class, following a pattern that allows to locate devices within the building. Analogously, SAREF4INMA reuses the same pattern to locate a production equipment in the factory.

In order to locate the ProductionEquipment, a factory layout can be created. A factory is represented by the s4inma:Factory class (which is subclass of the s4bldg:Building class) and can be further divided into smaller spaces using the s4bldg:BuildingSpace class. For the scope of SAREF4INMA, two types of BuildingSpaces are defined, namely Site and Area. A Factory can be further divided in sites, which according to IEC 62264 [i.11] are identified physical, geographical, and/or logical component groupings of a manufacturing enterprise. A Site can be divided in areas which are defined by IEC 62264 [i.11] as physical, geographical or logical groupings of resources determined by the site. An Area contains one or multiple work centers, which are a subclass of the s4inma:ProductionEquipment class and are defined according to IEC 62264 [i.11] as equipment elements under an area in a role-based equipment hierarchy that performs production, storage or material movement.

Note that as a subclass of saref:Device, a production equipment in SAREF4INMA inherits all the properties of devices defined in SAREF. This includes the possibility to associate a device (and therefore a production equipment) with a number of functions. For the purpose of SAREF4INMA, a new class of functions is created, namely the s4inma:ProductionEquipmentFunction class, which can be populated with subclasses that describe relevant functions, depending on the use case under consideration.

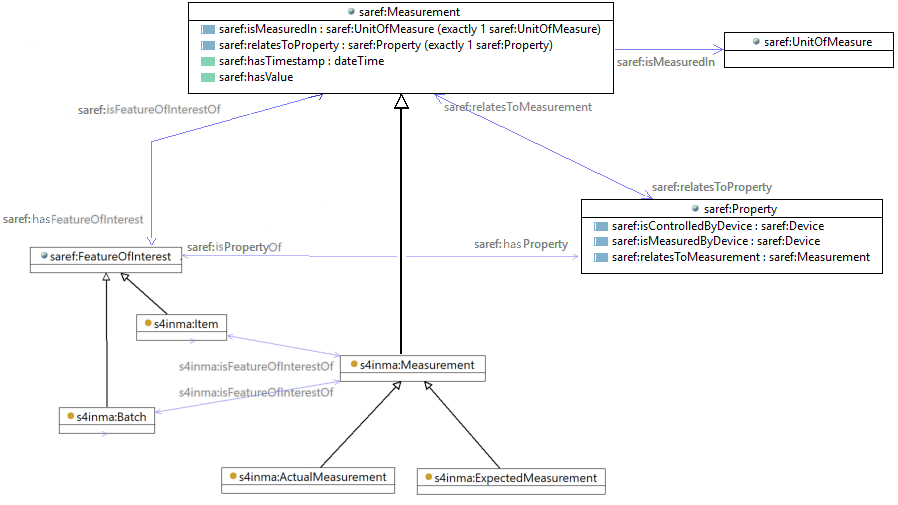

An important aspect of SAREF4INMA is the ability to trace back production process measurements to individual items or batches. The modelling of measurements in SAREF4INMA totally relies on the measurement model proposed in SAREF. This modelling include the saref:FeatureOfInterest class that provides the means to refer to the real world phenomena that is being observed in the given measurement (e.g. a shaver is an item resulting from a certain production process and it can be defined as the feature of interest of a temperature measurement made by a welding machine used to join different parts in the production of the shaver). The reader shall refer to the SAREF specification for details about the modelling of measurements. The following properties are reused in SAREF4INMA to complete the model of measurements:

Note that the present document includes details only for the new concepts created in SAREF4INMA, such as the s4inma:Measurement class. The classes of interest for measurements are shown in Figure 5.

The s4inma:Measurement class is defined as a subclass of the more general saref:Measurement class. The s4inma:Measurement class is further specialized in the s4inma:ActualMeasurement and s4inma:ExpectedMeasurement classes to describe whether a certain measurement is planned (i.e. expected) or is actually measured during the production process (i.e. actual measurement). This enables the calculation of deviations between planned and actual production process measurements.

As a saref:Device can recursively consists of devices, a ProductionEquipment in SAREF4INMA can also consist of other devices, such sensors and actuators. A device (e.g. production equipment and its sensors) can make measurements. These measurements can be related to a specific s4inma:Batch or s4inma:Item (which are both subclasses of the saref:FeatureOfInterest class) via thehasFeatureOfInterest relation. Moreover, according to the measurement model in SAREF, measurements are related to the property they observe (e.g. welding temperature) and its unit of measure (e.g. degrees Celsius).